Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

News

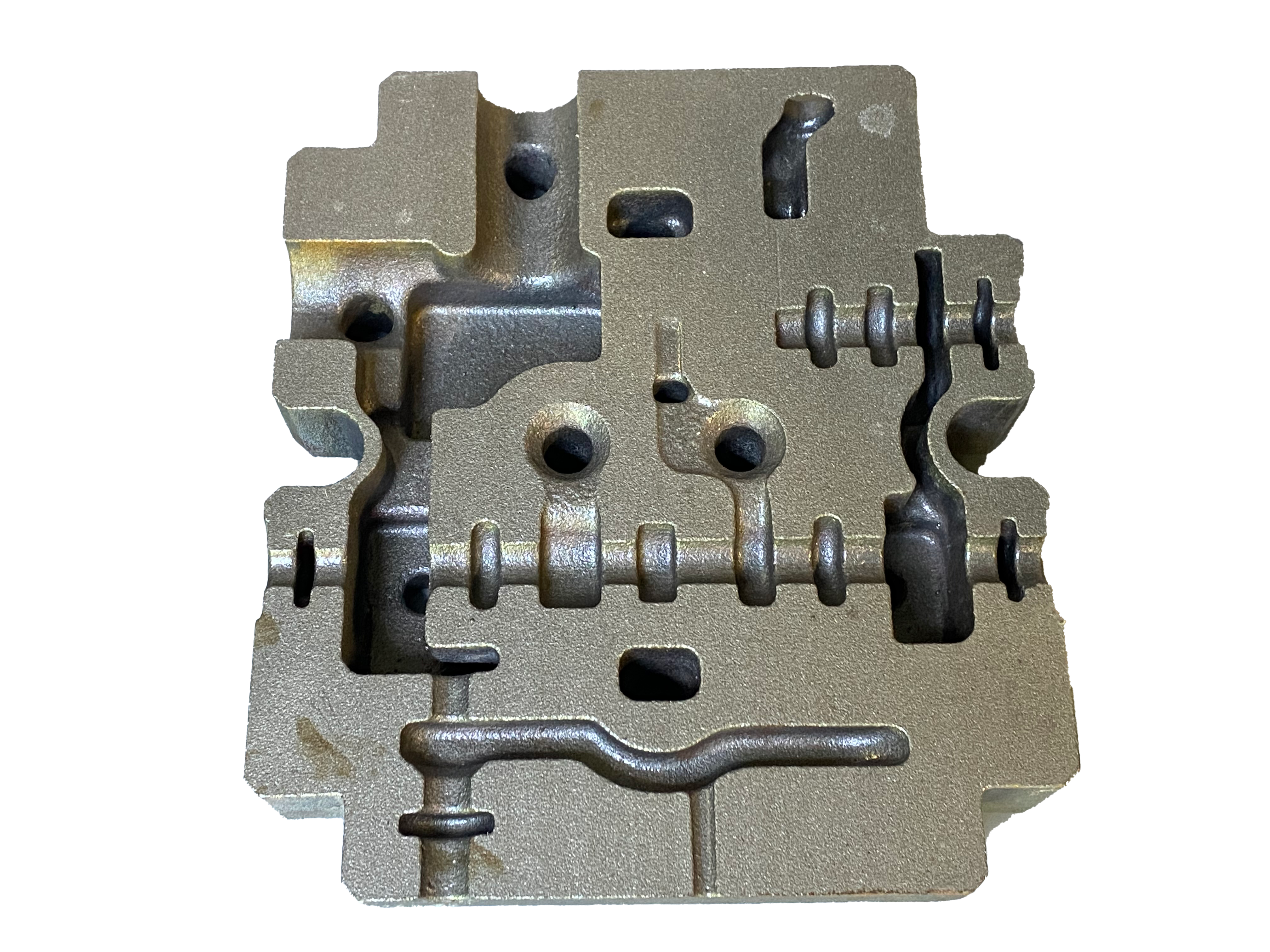

The Process of Precision Casting Mold

Some of the production processes of precision casting molds are also suitable for general casting processing. We sometimes encounter some problems in casting processing. For example, how to deal with black spots when polishing aluminum alloy die castings? At this time, it is necessary to reduce the concentration of spraying agent, change to other spraying agent, or increase the blowing time after spraying. How to deal with the pressure gun stuck in the gooseneck? With the device at room temperature, try rolling the hammer, if it doesn't roll, replace the barrel and remove the hammer.

If you want to deal with a stuck problem quickly, you should replace the material canister. When continuous blanking, pay attention to investigate whether there are bright spots on the machine above the head. If all parts are gray, the nozzle is clogged. At this time, the nozzle temperature should be appropriately increased, the nozzle tapping time should be reduced by 0.1 to 0.2 seconds, and the cooling water of the fixed mold should be slightly closed.

How to deal with the problem of easy cracking of thin-walled die-casting products?

This may be due to material problems or poor mold setting or improper selection of process parameters. Try to control the proportion of scrap to not exceed 30%, and the precision casting mold should not be kept for too long. Hydraulic sand cleaning is to shoot high-pressure water from the nozzle of the spray gun to the fine castings to be sorted through the pipeline, and rely on the kinetic energy and scouring action of the water flow to remove the sticky sand from the core and castings. In the finishing room, a reversing table is set at the bottom, and the spray gun is installed on the side wall, which can move up and down and reverse.

The high-pressure water flow can be shot to any part except the bottom surface of the casting. Sometimes, in order to better improve the efficiency of removing sticky sand on the surface of fine castings, abrasives such as quartz sand are introduced at the appropriate position of the spray gun to obtain high-speed water sand flow. This method is generally called water sand cleaning. After the water is blasted to clear the sand, after the mold is poured, the fine castings are boxed when they cool to the specified temperature, and they are immediately immersed in the pool.

Precision casting mold process

The shock wave can basically remove the sand attached to the inside and outside of the casting. The water blasting sand cleaning method has the advantages of short operation time and high power. It is widely used in steel casting workshops in my country. It is generally used to dispose of the carbon content below 0.35%. of steel castings. Wear resistance, in general, the higher the hardness of the mold parts, the smaller the amount of wear and the better the wear resistance.

Wear resistance is also related to the variety, quantity, shape, size and distribution of carbides in the material. When the blank is plastically deformed in the mold cavity, it both flows and slides along the surface of the cavity, causing severe conflict between the surface of the cavity and the blank, resulting in the failure of the mold due to wear. Corrosion resistance. When some molds such as plastic molds are working, due to the presence of chlorine, fluorine and other elements in the plastic, they decompose and separate strong corrosive gases such as HCI and HF after heating, which erodes the surface of the mold cavity and increases its surface roughness. , aggravated wear failure.

Strong and tough, most of the working conditions of the mold are very bad, and some often accept large impact loads, resulting in brittle cracking. Cold and heat fatigue resistance, cold and heat fatigue is the main way of failure of hot work molds, and this type of mold should have high cold and heat fatigue resistance. Fatigue cracking function. During the working process of the mold, under the long-term action of cyclic stress, fatigue cracking is often caused. The methods include repeated impact fatigue cracking with small energy, tensile fatigue cracking, touch fatigue cracking and bending fatigue cracking.

Conclusion

For more information about lost wax casting with stones,lost wax casting ceramic slurry,wax casting metal, we are glad to answer for you.